8in Compact Turning Center with Driven-tools

The Lynx 235M II is a new generation compact horizontal turning center with a higher rigidity and stability bed structure, equipped with an 18.5kW high performace spindle, which can meet the production needs of different customers from high-precision machining to large-scale production. With Driven-tools, turning and milling can be carried out on a single machine.

High rigidity

Structure design to prevent distortion and deformation of structure, resulting in the high rigidity and stability of the bed.

High efficiency

Equipped with high-performance spindle with 18.5 kW maximum power for higher machining efficiency.

Convenience of operation

Equipped with a rotating operation panel in order to improve the convenience of operation.

3rd party product

| Product | Description |

driven-tools(MT) driven-tools(MT) | BMT45P |

Video

| Model | Chuck size(S1) | Workpiece diameter | Workpiece length | Origin |

Lynx 235 II

(HTC) 1 TS 1 Turret

| 8 | Ø320 | 525 | Mainland China |

Lynx 235M II

(HTC) 1 TS 1 Turret

| 8 | Ø250 | 480 | Mainland China |

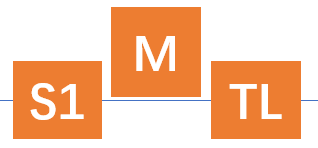

S1:Main-spindle S2:Sub-spindle TL:Tailstock H1:Mill-spindle T:Turret with static-tools M:Turret with driven-tools Y:Turret with Y-axis B:Turret with B-axis P:Gang with static-tools Q:Gang with driven-tools R:Gang with Y-axis

DN SOLUTIONS China Distributor

Shanghai PUMA

[Chinese] TEL (86)17625037271 email yllixiang@163.com

[English/Korean] TEL (86)17723941337 email shpm_info@163.com

Room 332, No 3152 Building, Hechuan Road, Minhang Qu, Shanghai, China

MACHINE SPECIFICATIONS

MACHINE SPECIFICATIONS

Not responsible for misprints or data errors. Actual product appearance may differ.

MTF mtfinder@163.com

driven-tools(MT)

driven-tools(MT)